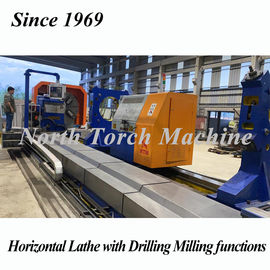

เครื่องกลึงเหล็กม้วนพร้อมระบบควบคุมซีเอ็นซี SIEMES หรือ FANUC

1. การสมัคร :เครื่องกลึงม้วนใช้อย่างมืออาชีพในการดัดแปลงม้วนเหล็กเก่าหรือกลึงม้วนเหล็กใหม่ เหล็กเส้น โดยโรงงานเหล็กเครื่องกลึงซีเอ็นซีแบบม้วนไม่เพียง แต่สามารถรับรู้ถึงกระบวนการกลึงของการกลึง, การต๊าป, การทำเกลียว, ร่อง ฯลฯ แต่ยังรวมถึงการหัน, อดีตวงกลม, พื้นผิว ฯลฯ

2. ข้อดีและคุณลักษณะของเราเกี่ยวกับเครื่องกลึงแบบหมุน:

เรามีโรงหล่อของเราเองซึ่งสามารถควบคุมและรับประกันคุณภาพการหล่อได้เป็นอย่างดี

รางนำ 4 รางพร้อมฝาครอบเหล็กยืดไสลด์ของเครื่องกลึงที่มีความแข็งแกร่ง ความมั่นคง และความแม่นยำหลังการเจียรสูงด้วยเครื่องเจียรโครงสำหรับตั้งสิ่งของขนาดใหญ่ 12 เมตรของเรา

ฟันเฟืองเป็นศูนย์ด้วยบอลสกรู

การตัดเฉือนหยาบและผิวสำเร็จในเครื่องกลึงซีเอ็นซีที่มีระบบควบคุมซีเอ็นซี SIEMENS หรือ FANUC

Tailstock คือระบบควบคุมไฟฟ้าพร้อมจอแสดงแรงดัน ซึ่งได้รับสิทธิบัตรระดับประเทศของเรา

แผงการทำงานคือ PLC Control ที่มีการออกแบบพิเศษของเราซึ่งได้รับสิทธิบัตรระดับประเทศ การใช้งานทำได้ง่าย เช่น CNC แต่ราคาถูกกว่าและง่ายกว่า CNC Control

ประเทศที่ส่งออกเกี่ยวกับเครื่องกลึงม้วน:

รัสเซีย, จอร์เจีย, ไทย, อาเซอร์ไบจาน, เอธิโอเปีย, อาร์เจนตินา, ออสเตรเลีย, ตุรกี, อิตาลี, นอร์เวย์, อินเดีย, อิหร่าน, Inodesia, บราซิล, ปานามา, โคลอมเบีย, ฯลฯ

3. พารามิเตอร์ทางเทคนิคของเครื่องกลึงเหล็กม้วน

| CK84--เครื่องกลึงม้วน |

| ชื่อ |

หน่วย |

CK8465 |

CK8480 |

CK84100 |

CK84125 |

CK84160 |

CK84200 |

| ประเภทรางนำ |

|

4 รางนำ |

4 รางนำ |

4 รางนำ |

4 รางนำ |

4 รางนำ |

4 รางนำ |

| แม็กซ์ เส้นผ่านศูนย์กลางของชิ้นงาน |

มม |

φ650mm |

φ800mm |

φ1000mm |

φ1250mm |

φ1600mm |

φ2000 มม. |

| ความกว้างรางของเตียงเครื่อง |

มม |

1000mm |

1100mm |

1400mm |

1600mm |

1800mm |

2000mm |

| เส้นผ่านศูนย์กลางของ Chuck |

มม |

φ1000mm |

φ1100mm |

φ1400mm |

φ1600mm |

φ1800mm |

φ2000mm |

| Chuck Jaw Length |

มม |

250mm |

250mm |

320mm |

320mm |

320mm |

320mm |

| Max.Length ของชิ้นงาน |

มม |

4000mm |

5000mm |

8000mm |

12000mm |

150000mm |

20000mm |

| น้ำหนักชิ้นงาน |

ตู่ |

10T |

18T |

25T |

32T |

40T |

50T |

| เส้นผ่าศูนย์กลางแกน |

มม |

φ190mm |

φ220mm |

φ260mm |

φ300mm |

φ300mm |

φ360mm |

| ความเร็วแกน |

รอบ/นาที |

5-260r / นาที |

2-165r/นาที |

2-130r/นาที |

2-130r/นาที |

2-80r / นาที |

0.5-80r / นาที |

| ขนาดเคล็ดลับแกน |

|

เมตริก 120 1:7 |

เมตริก 120 1:7 |

เมตริก 120 1:7 |

เมตริก 120 1:7 |

เมตริก 160 1:7 |

เมตริก 160 1:7 |

| แกน X จังหวะ |

มม |

50-325mm |

50-400mm` |

50-500mm |

100-625mm |

100-800mm |

200-1000mm |

| แกน Z จังหวะ |

มม |

1,000-4000mm |

1000-5000mm |

2000-8000mm |

2000-12000mm |

3000-15000mm |

3000-20000mm |

| แกน X ความเร็วที่รวดเร็ว |

มม./นาที |

2000 มม. / นาที |

2000 มม. / นาที |

2000 มม. / นาที |

2500 มม./นาที |

2500 มม./นาที |

2500 มม./นาที |

| แกน Z ความเร็วที่รวดเร็ว |

มม./นาที |

2500 มม./นาที |

2500 มม./นาที |

2500 มม./นาที |

2500 มม./นาที |

2500 มม./นาที |

3000 มม. / นาที |

| เส้นผ่านศูนย์กลางแกนหมุนของ Tailstock |

มม |

φ240mm |

φ290mm |

φ290mm |

φ320mm |

φ320mm |

φ410mm |

| Tailstock จังหวะแขน |

มม |

300mm |

300mm |

300mm |

300mm |

300mm |

300mm |

| วิธีการเคลื่อนย้ายของ tailstock |

|

การควบคุมไฟฟ้า |

การควบคุมไฟฟ้า |

การควบคุมไฟฟ้า |

การควบคุมไฟฟ้า |

การควบคุมไฟฟ้า |

การควบคุมไฟฟ้า |

| แรงตัดสูงสุดของเครื่องมือเดียว |

KN |

60KN |

80KN |

80KN |

80KN |

100KN |

150KN |

| แรงบิดสูงสุดของ Chuck |

KN·m |

13KN·m |

22KN·m |

33KN·m |

40KN·m |

90KN·m |

233KN·m |

| แรงตัดทั้งหมด |

KN |

45KN |

60KN |

70KN |

110KN |

160KN |

210KN |

| เครื่องยนต์ |

| กำลังมอเตอร์หลัก |

KW |

22KW |

37KW |

45KW |

55KW |

75KW |

128KW |

| กำลังมอเตอร์หล่อลื่น |

KW |

0.37KW |

0.37KW |

0.55KW |

0.55KW |

0.55KW |

0.55KW |

| ความแม่นยำ |

| ทรงกระบอก |

มม |

0.03/300mm |

0.03/300mm |

0.03/300mm |

0.03/300mm |

0.03/300mm |

0.03/300mm |

| ความเรียบ |

มม |

0.03/300mm |

0.03/300mm |

0.03/300mm |

0.03/300mm |

0.03/300mm |

0.03/300mm |

| ความหยาบ |

รา |

Ra3.2 |

Ra3.2 |

Ra3.2 |

Ra3.2 |

Ra3.2 |

Ra3.2 |

| ขนาดเครื่อง |

CM |

600*200*140 |

750*220*165 |

8100*275*195 |

1000*310*215 |

1050*320*240 |

1250*360*265 |

| น้ำหนักเครื่อง |

ตู่ |

20T |

23T |

26T |

35T |

46T |

65T |

4. บริการหลังการขาย

1. วิศวกรพร้อมสำหรับการติดตั้งเครื่องกลึงม้วน การว่าจ้าง และการฝึกอบรมที่โรงงานผู้ใช้

2. Fedex, DHL ฯลฯ สามารถจัดหาอุปกรณ์เสริมเครื่องจักร เช่น ขากรรไกร เกียร์ แบริ่ง เครื่องมือตัด ฯลฯ ได้ทันทีโดย Fedex, DHL ฯลฯ เพื่อป้องกันไม่ให้การผลิตสิ้นสุดลง

3. การรับประกันคุณภาพของเครื่องกลึงม้วนคือ 12 เดือน

สำหรับรายละเอียดเพิ่มเติม โปรดติดต่อเรา

ขอบคุณที่ให้ความสนใจ

แท็ก: เครื่องกลึงโรล, เครื่องกลึง CNC, เครื่องกลึงแนวนอน, เครื่องกลึงหนัก, เครื่องกลึงธรรมดา, DRO LATHE

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร!

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร! กรุณาตรวจสอบอีเมลของคุณ!

กรุณาตรวจสอบอีเมลของคุณ!  ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร!

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร! กรุณาตรวจสอบอีเมลของคุณ!

กรุณาตรวจสอบอีเมลของคุณ!